Single Seat Globe Control Valve is pressure imbalance structure products, one of two basic guide plunger valve core, the floating sleeve compression type, from the seat structure, modular design, the flow capacity is big, high controlling precision, adjustable range, can achieve minimal flow control, structure is simple, reliable, good seal performance, the scene is easy to maintain. Is suitable for the pressure difference is not big, the seat leakage and high control precision.

Single Seat Globe Pressure Control Valve advantages:

According to the needs of the working conditions, different materials and surface hardening treatment can easily be chosen to meet the requirements of each function module of trim to improve its performance of the corrosion, cavitation and erosion resistant, lengthen service life.

2. Pressure Control Valve body

The body of LN8 Single Seat Globe Valves consists of two passages from upper and lower, forming a shape like letter "S". The design of an elliptical section reduces the flow resistance and turbulent flow to keep the flow fluent. The flap in the middle of upper passage can reduce the eddy flow and increase the flow capacity.

3. Single Seat Globe Valve Actuator

The standard mate of Single Seat Globe Valves is AM8 Multi-spring pneumatic diaphragm actuator, which can be used in many conditions with the features of strong output force, high reliability, long lifespan and extensive applications. The output force changes with the number of springs. The high stress resistant diaphragm, bearing maximum pressure of 0.5 MPa air supply, gives globe valves a reliable shutoff. This type of actuator has a long life cycle with more than 1 million times.

A. New function modular design B. Self-centring seat design

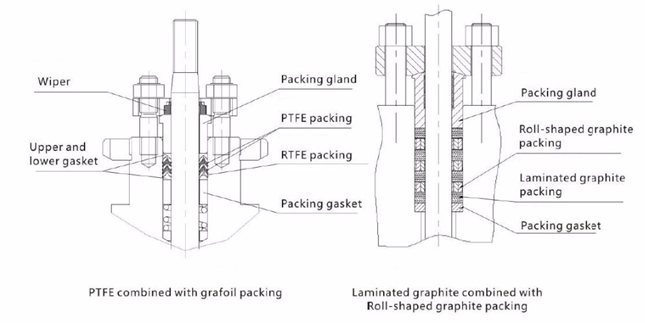

The packing box assemblies are also optimized. Seal ring in the gland flange can prevent the dirt from entering and protect the packings. The V-ring is added with an U-groove and its angle is changed from conventional 90 to more efficient 85. The package is a combination of alternating pure PTFE and PTFE with grafoil. When the temperature of fluid is above 200℃, the packing will be made by grafoil.

We have been the leader in the valve industries, we have our own design and production system.

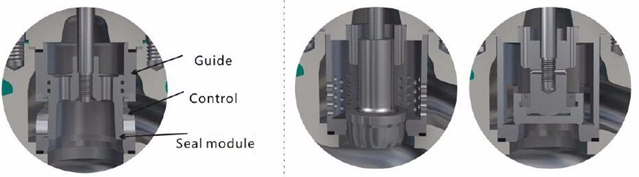

High performance Pressure Control Valve are designed strictly on the basis of the IEC standard. They are the latest self-innovated modularized straight stroke control valves of SUPCON. We divide the trims into three modules, namely guide, control and seal module. We provide the best solution according to the function of each module and make action, control and seal more reliable.

Each index, linear, hysteresis, dead zone and leakage, for example, is full compliance with national standards.

Note: For below measured results, take LN8100 top guide single seat valves (PN110) as an example.

Test Items | National Standard | CSV Standard | Measured Results |

Seat Leakage | 0.06 L/min | 0.064 L/min | 0.01L/min |

Rated Travel Error | +2.5% | +2% | 1.32% |

Start Error | ±2.5% | ±2% | 0% |

End Error | ±2.5% | ±2% | 0.08% |

BasicError | ±1.5% | ±1% | -0.52% |

Hysteresis | 1.5% | 1% | 0.16% |

Dead Band | 0.6% | 0.4% | 0.38% |

- Single Seat Globe Pressure Control Valve is easy to maintain:

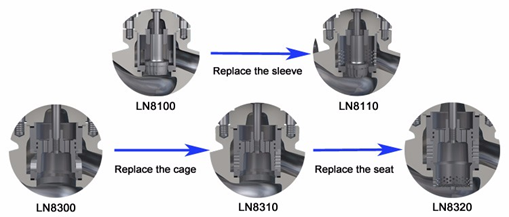

The unique platform and modul design make it jammy to remove and displace the parts without special tools, and moreover, jammy to change the type of the valves only by changing few parts. A variety of material combinations is optional for the parts.

TECHNICAL PARAMETERS

Nominal Size | DN15 ~ DN300 |

Pressure Rating | PN16/25/40/63/100;CL150(PN20)/300(PN50)/600(PN110) |

Operateing Temperature | -196℃~ 593℃ |

Characteristics | Equal percentage, linear, quickly open |

Rangeability | 30:1、50:1、 100:1 |

Seat Leakage Class | ANSI B16.104: IV、V、VI |

Body Material | WCB/WCC/LCB/LCC;WC6/WC9;CF8/CF8M;4A/5A etc. |

Trim Material | 630/316/316+ST/316nitriding/316+Ni60/316+WC etc. |

Seal Material | PTFE+ graphite v-shaped packing, flexible graphite ring packing, graphite +PTFE braided packing etc. |

Applications Of Globe Control Valve

Globe valves are used in systems where flow control is required and tightness is also important. When the leak tightness and safety are mainly considered, it can be used for high-level exhaust holes and low-level drainage holes. Otherwise, a gate valves can be used for drainage and venting. It can be used in water, chemicals, air, lubricants and almost all services that do not require pressure drop. The globe valves is also used as an automatic control valves, but in this case, the valve stem is a smooth stem, not a thread, and is opened and closed by the lifting action of the actuator assembly. At the same time, the globe valve is also a linear motion valve, which is widely used for stopping, starting and throttling. The existence of a shut-off valve makes system operation easier. Some of the most typical applications for globe valves include cooling water systems, fuel oil systems, feedwater or chemical feed systems, boilers and major steam discharge and discharge ports, and turbine lubricant systems. Select different types of valves according to the temperature range required by the work.